Engineering & Design for Additive Manufacturing

Made Simple.

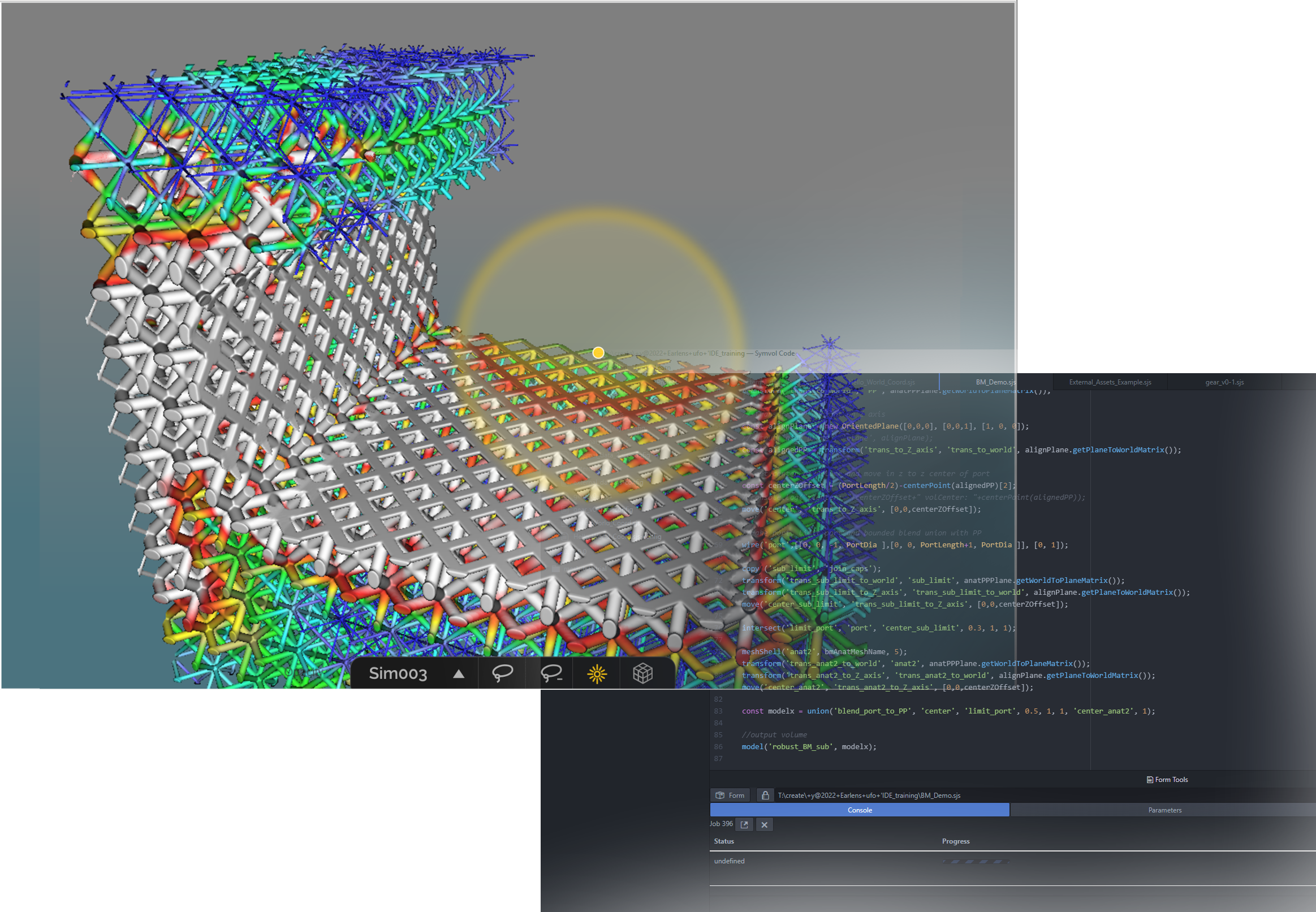

Whether you need to enhance objects with performance tuned meta-materials, drive net shape additive manufacturing, or offer on-demand custom fit medical devices - Uform makes it simple.

Request a DemoVirtualized Hyper Tooling.

Reduce your tooling costs by up to 10x.

Build, retool, optimize and configure manufacturing applications and processes in days or even hours, not months. Easily develop and deliver complex workflows by plugging together modules and operations through 3D modeling, scripting & streamlined GUIs. Build your digital factory today.

Discover More Advantages

Materialize

Reality.

Automate optimization & customization of every part.

Using Uform's foundational Real Volume™ technology, seamlessly mix mechanical geometries, organic shapes, micro-stuctures and scan data at any complexity or detail. Go beyond the virtual. Shape the material world.

Discover More Advantages

Rules Based Engineering & Manufacturing.

Reduce your manufacturing waste, downtime & churn to near zero.

Using closed loop simulation and machine learning: automatically generate geometry to meet any constraint; make corrections to customized products; remove errors in the manufacturing line before they happen. Count on knowing all your models meet target specifications and can be changed instantly based on new needs. Make your own rules.

Discover More AdvantagesMatter Development Kit &

Cloud Production Platform

A full stack 3D development kit for advanced volumetric design, engineering and manufacturing processes.

Solve your workflow challenges with bespoke applications that will ensure your products are developed quickly, precisely, always ready for print, and drive printers at their full capacity.

Symvol Shape Engineer

For shape engineers/designs in pre-production R&D or smaller SME testing concepts before launching into full manufacturing production.

Request More InfoSymvol Factory

For companies wanting to build-out a custom factory in the cloud to service their digital production line of personalized goods.

Request More InfoDesktop Software for 3DP & AM

MeshUp is a super simple, always watertight, 3D modeling & mashup tool for meshes that is built for painless 3D printing. Without effort, a creator can combine mesh or scan data & easily 3D print the models.

Buy

Symvol™ for Rhino is a Real Volume™ based 3D modeling package, built as a plugin to Rhinoceros®. Create mechanical & organic parametric models that are always watertight, at any desired scale & complexity.

BuyAdvantages

Leveraging the power of Uform's volumetric modeling engine offers powerful advantages.

- Symbolic Modeling

- Robust and fail safe parametrization of any aspect and relationship in a model.

- Direct Fabrication & 3D Printing

- Output STL meshes at any resolution, or move to higher quality slices for direct machine fabrication.

- Always Watertight

- Guaranteed model integrity & watertight modeling. There is never a need to run repair processes.

- Unlimited Computation

- Using true grid based computation, tasks are no longer hardware limited and can be set to complete within set time frames.

- Dynamic Scalability

- Servers scale to handle spikes and heavy computation on demand, saving resources for when they are needed.

- Costs Proportional to Success

- Monthly expenses are tied to computation use and the export of production data.

Engineering & Training

Our network of expert modelers and developers can provide assistance to your team at any stage needed, from customizing an application suited perfectly for your business needs, to consultation on blue-sky R&D, to the creation of nature-like designs that can take full advantage of advanced manufacturing techniques.

Symvol App Dev

We can help your team build custom end-to-end design & manufacturing applications, or integrate missing pieces of functionality seamlessly into existing workflows.

Engineering For AM

Together we can help you generate optimized digital part libraries with unlimited cellular & micro structures that can change topologies based on machine learning & simulation.

Consulting & Training

Everything from scanning to design to manufacturing, our team has the expertise to help you leverage the technology.

Universal Form Corp

Born as an international collaboration using new foundational 3D technologies, Uform's founders set out to build a superior class of engineering, modeling and manufacturing tools that can fully realize and drive the advancement of 3D printing and robotic manufacturing.

Unlike most tech companies today, Uform has been fueled from day one by providing true value to our customers and an academic foundation of open collaboration. Everyday our engineers help customers solve hard problems in the field to often build the difficult or impossible. This keeps us closely tied to the challenges and needs of real users and the marketplace that translates into a level of customer service and deep understanding that is hard to find.

Based on Uform's foundational technology, our team believes in developing robust, long lasting, open standards and software that can be trusted and a larger vision for a new form of manufacturing and building that operates in concert with natural systems, not against them.